This procedure shows you how to set up a new replenishment process which uses the minimum/maximum replenishment strategy. When inventory falls below the minimum level, work will be created to replenish the location. The procedure also shows how to use fixed picking locations to allow restocking even if inventory falls below the minimum level, and how to enable the replenishment process to run regularly using a batch job. These tasks would typically be carried out by a warehouse manager. You can run this procedure in the USMF demo data company using the example values below, or can run it on your own data. If you're using your own data, make sure that you have a warehouse that's enabled for Warehouse management processes.

Create a fixed picking location

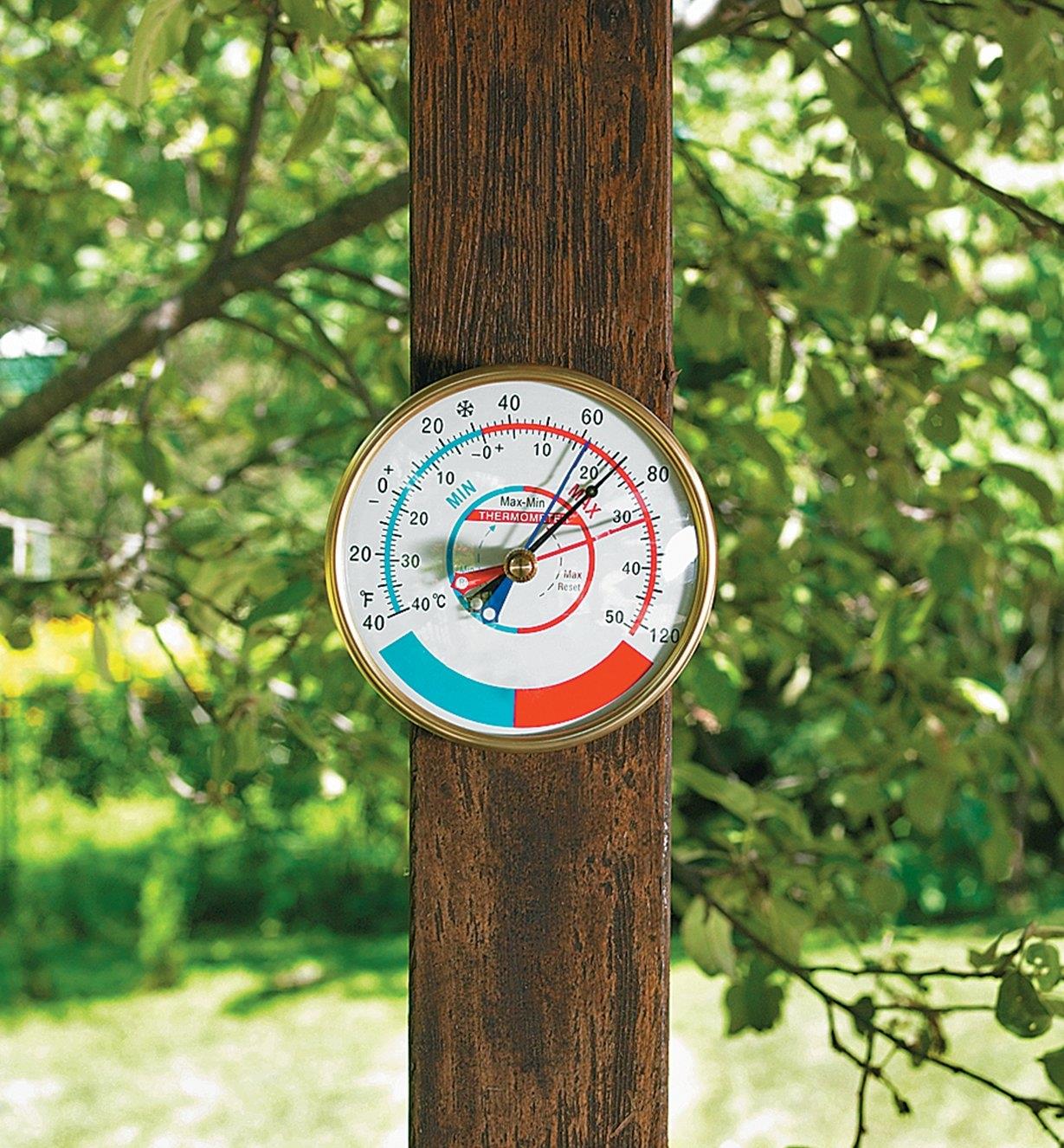

Hence, we determine the global max and min by considering points in the interior of the disk and on the circle. An alternative method for finding the maximum and minimum on the circle is the method of Lagrange multipliers. Maxima and Minima for Functions of More than 2 Variables. Minimax is a kind of backtracking algorithm that is used in decision making and game theory to find the optimal move for a player, assuming that your opponent also plays optimally. It is widely used in two player turn-based games such as Tic-Tac-Toe, Backgammon, Mancala, Chess, etc. In Minimax the two players are called maximizer and minimizer. A min/max inventory system is an approach to managing materials or goods in which the business sets a minimum threshold and a maximum level of inventory to hold. When the current supply of an item reaches the minimum level, a new order is placed. When new materials or goods are ordered, the total supply on hand cannot exceed the maximum amount. Minimum and Maximum Use the minimum and maximum keywords to specify the range of possible values: type: integer minimum: 1 maximum: 20 By default, the minimum and maximum values are included in the range, that is: minimum ≤ value ≤ maximum To exclude the boundary values, specify exclusiveMinimum: true and exclusiveMaximum: true.

Sql Min Max

- Go to Navigation pane > Modules > Warehouse management > Setup > Warehouse > Fixed locations. This is an optional task for min-max replenishment, but if you use fixed picking location, this allows stock to be replenished even if it falls below the minimum level, because the system can determine which items need to be replenished, even if there aren't any left.

- Click New.

- In the Item number field, enter or select a value. If you're using USMF, you can select item A0001.

- In the Site field, enter or select a value. If you're using USMF, you can select site 2.

- In the Warehouse field, enter or select a value. If you're using USMF, you can select warehouse 24.

- In the Location field, enter or select a value. If you're using USMF, you can select CP-003.

- Close the page.

Create a replenishment location directive

- Go to Warehouse management > Setup > Location directives. Location directives are used to determine where items should be picked from in the replenishment process.

- In the Work order type field, select 'Replenishment'.

- On the Action Pane, click New.

- In the Name field, type a value.

- In the Work type field, select 'Pick'.

- In the Site field, enter or select a value. If you're using USMF, you can select site 2.

- In the Warehouse field, enter or select a value. If you're using USMF, you can select warehouse 24.

- Click Save.

- In the Lines section, click New.

- In the list, mark the selected row.

- In the To quantity field, enter a number. For example, you can set it to 9999.

- Select the Allow split check box. If you select this option, the work creation process will allow work line quantities to be split across multiple locations.

- Click Save.

- In the Location directive Actions section, click New.

- In the list, mark the selected row.

- In the Name field, type a value.

- Click Save.

- On the Action Pane, click Edit query. You can edit this query to add restrictions where inventory can be selected from in the replenishment process. For example, it could be that inventory should only be used from the Bulk area of the warehouse.

- Click OK.

- Close the page.

Create a replenishment work template

- Go to Warehouse management > Setup > Work > Work templates. The work template is use to guide the system as to how the min/max replenishment work must be created. As a minimum, there must be a work template line for a pick and a put. The work template will say that it's Invalid until all the necessary information has been filled in.

- In the Work order type field, select 'Replenishment'.

- On the Action Pane, click New.

- In the Work template field, type a value.

- Click Save.

- In the Work template details, click New.

- In the Work type field, select 'Pick'.

- In the Work class ID field, enter or select a value. This should be a work class related to replenishment. If you're using USMF, select Replenish.

- In the Work template details, click New.

- In the list, mark the selected row.

- In the Work type field, select 'Put'.

- In the Work class ID field, enter or select a value.

- Click Save.

- Close the page.

Create a new replenishment template

Min Max Calculator

- Go to Warehouse management > Setup > Replenishment > Replenishment templates. The replenishment template is used to define the items and quantities, and the location to replenish.

- On the Action Pane, click New.

- In the Replenish template field, type a value. Give the template a name to indicate that it's for min/max replenishment.

- In the Description field, type a value.

- Select the Allow wave demand to use unreserved quantities check box. If you select this option, it enables wave demand replenishment to consume quantities that are related to min/max replenishment. For example, this might be useful if the min/max replenishment work isn't processed immediately, to avoid unnecessary demand replenishment work from being created.

- In the Replenishment template details, click New.

- In the Sequence number field, enter a number.

- In the Description field, type a value.

- In the list, mark the selected row.

- In the Replenishment unit field, enter or select a value. For example, select pcs. This setting is mandatory. It allows you to specify a different unit of measurement for replenishment work compared to the unit specified for the minimum and maximum stock levels in this template.

- In the Work template field, enter or select a value. Choose the work template that you created earlier.

- In the Minimum quantity field, enter a number. Select the minimum quantity that should trigger the replenishment. For example, set this to 50. It is possible to leave this set to zero, if you're replenishing a fixed location and the Replenish empty fixed locations option is set to 'Yes'. We also recommend that you select the Replenish only fixed locations option for performance reasons.

- In the Maximum quantity field, enter a number. For example, set this to 100.

- In the Unit field, enter or select a value. Assign the unit for the minimum and maximum quantities. For example, set this to pcs.

- Select the Replenish empty fixed locations check box. Select this check box to replenish fixed locations when they are empty. Otherwise, only the locations where there is a quantity on hand will be replenished.

- Select the Replenish only fixed locations check box.

- Click Select products. This is the place to define which products should be replenished. If the Fixed picking locations option is selected, you also need to define the locations in this query. Variant-specific queries are available as well product-specific queries.

- Select the Items row.

- In the Criteria field, type a value. Select the items that should be replenished at the fixed locations. For example, type A* to select all item numbers beginning with A.

- Click Add. Add the Location entity (unless it already exists) to be able to restrict the replenishment work to the fixed picking locations within a specific area of the warehouse.

- In the list, mark the selected row.

- Set the Table field to 'Locations'.

- In the Field field, select 'Location profile ID'.

- In the Criteria field, enter or select a value.

- Click OK.

- Close the page.

Set the replenishment process to run as a batch job

- Go to Warehouse management > Replenishment > Replenishments. The Replenishments page allows you to set up replenishment to run as a batch job, or to require that it's started manually.

- Click Filter.

- In the list, mark the selected row.

- In the Criteria field, enter or select a value.

- Click OK.

- Expand the Run in the background section.

- Set the Batch processing option to 'Yes'.

- Click Recurrence.

- Select the No end date option.

- Set the Recurrance pattern. For example, select Days.

- Click OK.

- Click OK.

Note

Min Max Podcast

Can you tell us about your documentation language preferences? Take a short survey.

Min Max Problem

The survey will take about seven minutes. No personal data is collected (privacy statement).